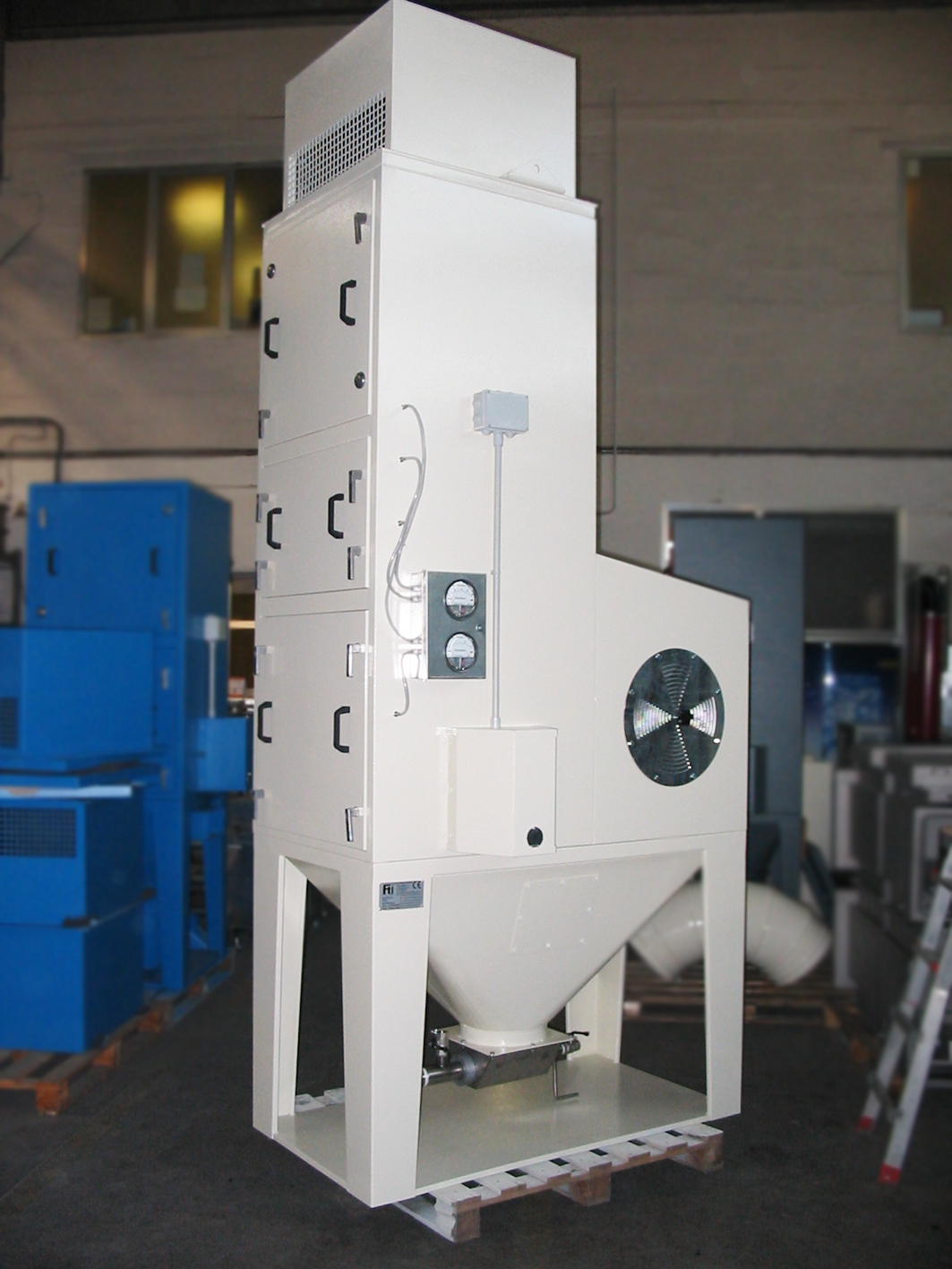

The Dust Collectors FTM are compact unit for intermittent working and equipped with a mechanical shacking cleaning system. Their application provide the solution of a wide variety of dust problems in all industrial sectors and particularly in chemical and pharmaceutical industries. The FTM are available in different basic constructions with filtration areas from 4 to 50 m2, they are made with a high quality filter fabric for an intermittent service. The cleaning of the filter by vibrator is automatically activated when the fan is switched off

FTM-V TYPE

Standard integral dust collectors FTM complete with fan, filter assembly with cleaning device, hopper and dust container. This unit can be applied directly on dust generating as: grinders, borers, crushers, drills, tabletting machines, mills, mixers, saws, polishers, sanders.FTM-P TYPE

Standard integral dust collectors FTM complete with fan, filter assembly with cleaning device, hopper and dust container. This unit can be applied directly on dust generating as: grinders, borers, crushers, drills, tabletting machines, mills, mixers, saws, polishers, sanders.FTM-W TYPE

Venting dust collectors FTM with filter assembly and cleaning device only in flanged case to be installed on silos or other storage vessel under pressure. In this case the collected dust is deposited directly into the silo or storage vessel.FTM-EV TYPE

dust collectors FTM with filter assembly and cleaning device, hopper and dust container but without fan. It is designed for venting application when it is necessary to site the unit away from the silo.Accessories

Secondary filter

It is an housing with front access door mounted on top of the unit that can hold absolute filters (HEPA) or activated carbon filters. The main purpose of the secondary filter is to keep possible fine dusts left from FTM unit or to act as safety device if the main unit filter element gets demaged. For special applications, mainly in pharmaceutical industry, absolute filters (HEPA) with efficiency H 13 EN 1822 can be inserted. Special activated carbon cells can be installed as secondary filter when the unit is handling gas or industrial vapours. The carbon used is of vegetable origin subjected to an activating treatment that gives to the carbon a special porosity and consequently a very high adsorbent capacity. We remember that the adsorption is a physical process through which the molecules of gas are fixed to the surface of the media. We suggest the use of the standard carbon up to a temp. of 60° C and to a relative humidity of 70%.Silencer

The dust collectors FTM can be fitted with an acoustic diffuser capable of reducing noise level at 1 meter from the unit. This silencer is a box on the top of the unit, deflecting the air from the fan, lined with special sound-adsorbent material.Pressure balance pipe

The dust container may by lined with a polyethilene bag to facilitate the removal of particolar or noxious dusts. To prevent the bag from being sucked into the unit a detachable pressure balance pipe is connected between the hopper and the container for this purpose. (This pipe is always supplied as standard with the FTM 30 and 45, while for other models is available on request).

Dust Collectors FTM