The air carbon filters Filtrotecnica Italiana are born on our test beds for solving pollution problems from odors, gases and vapors. Two basic types of activated carbon filters to solve so effective is the need for interventions on already existing installations that more complex solutions in the new installations. In fact it was observed the modular standard according to international dimensions and in the same time giving also the possibility of partial systems to very low air capacity.

The models in production, both of the disposable type, are:

Cartridges modules type C 2000/6 and C 4000/12

Cartridges modules type C 2000/8 and C 4000/16

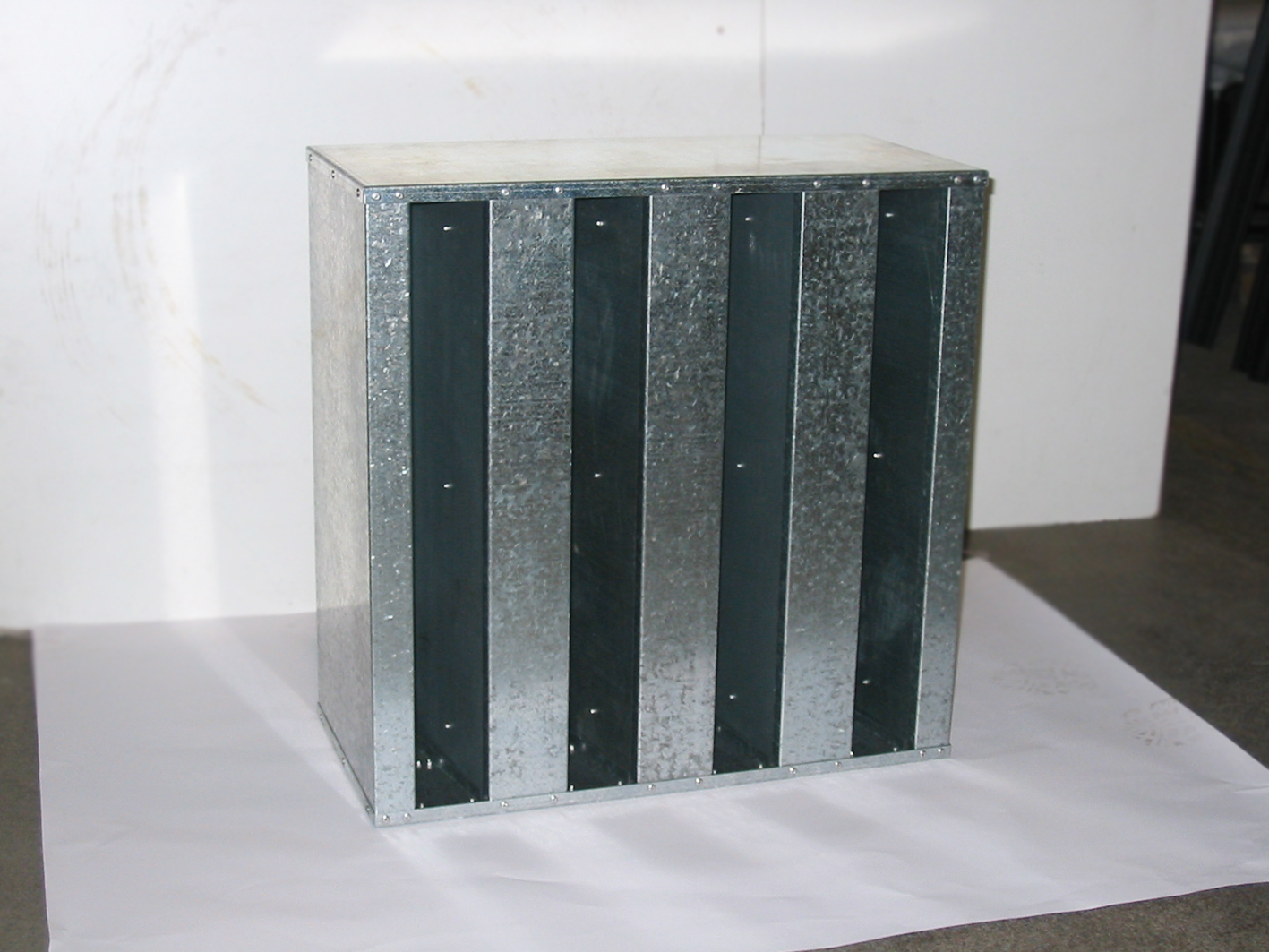

Safety beds cells type L 600/305 and L 1200/610On request the activated carbon cartridges modules can be supplied with their ducted housing type FT MODUL. In the most critical application the activated carbon safety beds cells can be supplied with Canister housings for an easy and safe change of the filter by means of plastic barrier–bags (bag in/bag out).

Activated carbons are microporous materials of preferably vegetable origin which have undergone an activating treatment that gives the carbons an outstanding porosity and therefore a very high internal surface (till 1700 m2/g) suitable to hold or better to adsorb in their active pores, in a selective manner, a wide range of molecules with more or less high efficiences (see list in the last part of bulletin). The activated carbon normally used are obtained from many raw materials as walnut cocoanut husks, peat, wood, etc. In various shapes. The shouge in small cylindres with a diameter of 3÷4 mm is the most commonly emploied in the aeriforms thanks to the reduced pressure drop of the filter beds and to the high abrasion resistance.

Each type of carbon is idendified by a series of parameters, generally shown on technical schedules, that define its properties:

• The apparent density that represents the carbon quantity in the considered volume unit

• The ash contents that represents the non active percentage of material

• The moisture contents that represents the water percentage of the carbon

• The benzene index that indirectly represents the performance of the carbon in comparison with predetermined substances acting as reference indicators

• The iodine index that indirectly represents the active surfaceGas adsorption units are wholly manufactured

They are designed as per Machine Directives as well as UNI EN ISO 9001 regulations. Each unit is sized on customer’s request with regard to working pressure and temperature.Gas adsorption unit applications are various:

– Air-cleaning for limited quantity of pollutants;

– Vapour adsorption

– Exhaust gas treatment

– Air cleaning during filling and emptying operations of tanks reactors, hydraulic circuits containing and/or pollutants.Filtrotecnica exhaust gas adsorption units are extremely cheap, very easy to install and can operate in rather limited areas.

Download catalog adsorbers attached to test all substances that can be absorbed by activated carbon and those which can not be absorbed by that principle.

Air Carbon Filters